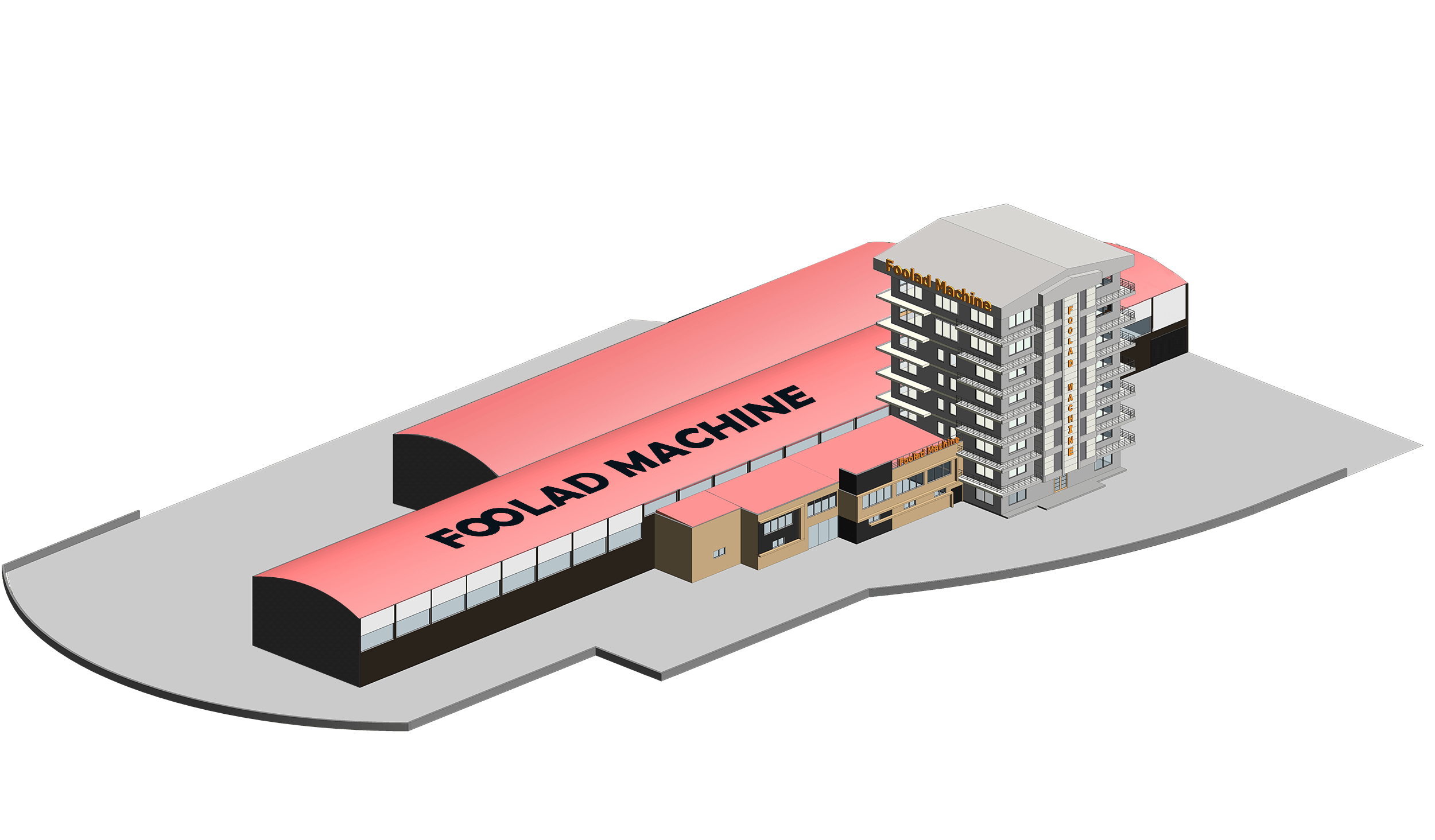

Foolad Machine

Modular Buildings

Machinery

Steel Structure

CFT

27+ years of experience

Our History

Foolad Machine Neka (1995) started it’s professional path in building machinery & steel structure based on the 27 years of experience and now after years of studies and work has seceded to design, build and make every part of a modular building.

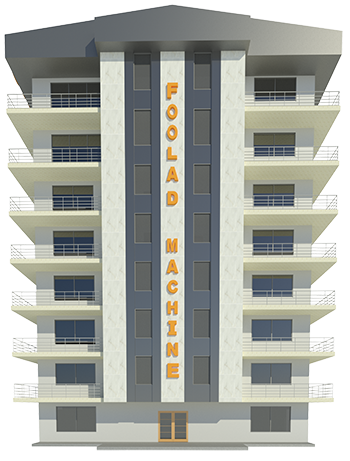

Our dream is providing safe, beautiful and cheap housing to every member of the society!

Our products

Safe & cheap housing

Over the past few decades, the emergence of the prefab category has caused fundamental changes in the world’s construction industry. In fact, prefabrication refers to off-site construction or the construction of elements in industrial units and their transportation and assembly at the project site. The use of these prefabricated elements was developed in the mid-1960s, and today, various types of prefabricated modular construction techniques are common throughout the world, and there is fierce competition between them. Concrete vs. steel, precast concrete vs. in-situ concrete, etc., but this product is produced under controlled factory conditions with excellent quality and having parameters such as greater resistance, saving construction costs, and more favorable environmental performance of this type of construction. The on-site instrument has made the project superior to its traditional type.